News Center

Current location:home>NEWS > Industry information

Background

With the rapid development of the dairy industry, the output of raw milk and dairy products has been dramatically increased, with a great variety of dairy products and a fundamental leap in quality. High-tech applications such as in genetic, enzyme, microbial, high-pressure, and cold sterilization are getting widely applied in dairy production.

Enzymes are catalytic proteins produced by living cells that participate in various biochemical processes in the body. Enzyme technology shows its unique charmwhen compared to traditional chemical processes such as acidic processing. It overcomes the harmful by-products produced by chemical methods and provides a healthier, environmentally friendly, safe and effective solution for food processing. These characteristics have greater advantages as to traditional chemical reactions. Enzymes can replace many chemical agents in the food industry, allowing production become more natural and efficient.

I. Overview

Milk is the perfect food. Increasing the intake of milk is an ideal source of adequate calcium. In the new dietary guidelines, the Chinese Nutrition Society suggests “Drinking milk anddairy products regularly” as a major approach to the national residents for improving the nutritional status of the whole population.

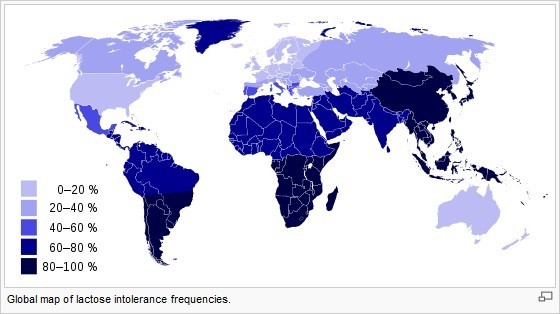

In China, about 90% of adults are lactose intolerant.

Eating low-lactose dairy products is one of the effective ways to solve lactose

intolerance. Lactases from different sources have been developed to produce

lactose-degraded dairy products. The method of lactase treatment of milk is to

directly mix lactase into pasteurized milk. During storage, lactose can be

converted to glucose and galactose by hydrolysis. The manufacture of low

lactose hydrolyzed milk can improve the flavor, sweetness and nutritional value

of milk; the application in fermented milk can accelerate the reaction and

improve the fermentation efficiency, so that the milk emulsion has a unique

frankincense flavor, relatively prolonging the shelf life of the product While

the application in condensed milk can prevent the lactose from crystallizing

during concentration to make the product taste fine and increase the sweetness,

and reduce the amount of sucrose to inhibit bacteria and improve the quality.

二、Latest advances in enzyme technology in dairy research

1. Modification and degradation of lactose to prevent the occurrence of lactose intolerance.

Lactose is the main carbohydrate in milk, and it is also an important source of energy supply for breast-feeding infants and galactose to ensure brain development. It can promote the diffusion and transport of calcium and facilitate absorption, and has the effect of intestinal consolidation.. Failure in degrading will lead to a series of lactose intolerance symptoms. People who’s suffering from lactose intolerance can not degrade the lactose in milk into glucose or galactose that can be directly absorbed into blood, mainly because the intestinal mucosal cells of the body cannot produce enough lactase to break down the lactose, so lactose intolerance is actually lactase deficiency. Lactase deficiency is a widespread worldwide problem that is actually more prevalent in Asians and Africans.

Figure Global incidence of lactose intolerance (Source: Wikipedia)

2. Hydrolyze milk protein to prevent milk allergy.

Milk protein allergy is a very serious problem for certain people, especially those with congenital allergies. The main clinical symptoms are angioedema, urticaria, atopic dermatitis, respiratory symptoms, acute abdominal pain, diarrhea, vomiting and allergic reactions. Lactoglobulin or casein, an allergen in certain populations, could be adsorbed into the intestinal mucosa by virtue of its immunogenic protein, which can avoid the immunoglobulins present in intestinal mucosal epithelial cells. The action of the immune system is generated, which causes an allergic reaction among some infants and adults, and symptoms such as rash and asthma.

The peptide obtained by hydrolysis the selected protease not only improve the accessibility of digestion and absorption, but also reduces the antigenicity of the epitope of the antigen significantly through hydrolyzing the fragment , thereby preventing milk allergy. Compared with the free amino acids mixture, milk protein hydrolysates have the advantages of good flavor, high absorption rate and low osmotic pressure. Generally, the hypoallergenic casein and whey protein are prepared by enzymatic hydrolysis, heat treatment or ultrafiltration. Irrespective of a slight effect on the immunogenicity of milk protein, heat treatment can affect the configuration of milk protein, increase the contact between proteolytic enzyme and substrate, and obtain hypoallergenic protein hydrolysates.

3. Milk contains a variety of antibacterial ingredients, with multiple effects.

Ingredients such as immunoglobulin, lactoferrin, lactoperoxidase and lysozyme, can prevent the occurrence of cow mastitis, inhibit the growth of microorganisms during the storage of raw milk and dairy products, but only effective for a certain period of time. Lactoperoxidase is the main substance to prevent microbial contamination. Each lactoperoxidase molecule contains an iron atom. The lactoperoxidase itself has no antibacterial activity. It is naturally composed with hydrogen peroxide or thiocyanate into an antibacterial system, also called lactoperoxidase system, has antibacterial and antiseptic effects. Lactoperoxidase inhibits Gram-negative bacteria (including E. coli and Salmonella strains) and Gram-positive bacteria. Its bacteriostatic effect is related to 5H value, temperature and bacterial number. The antibacterial properties of the lactoperoxidase system are also increasingly applied in animal production and clinical medicine. For example, the lactoperoxidase system that activates the raw milk itself can extend its shelf life; adding sodium thiocyanate into raw milk can prevent spoilage; adding lactoperoxidase into milk substitute instead of antibiotic can prevent the occurrence of drug resistance

Enzyme preparations are getting widely used in the food industry, the dairy industries particularly. With the development of new technologies such as genetic engineering, the potential of enzyme engineering applications is expected to be further developed. Looking forward, enzyme preparations, a kind of clean technologyoriginated from nature itself,, has a broad application prospect in finding innovative, economic and environmentally friendly methods to provide for providing solutions to industrial problems throughout the world.

Tel: +86-730-8422581 +86-730-8421181

Fax: +86730-8422580

E-mail:sales01@yyrksw.com

Add: No. 2 Building, Lingang Incubation Base for Scientific and Technological Entrepreneurship,Yungang Road, Yueyang Chenglingji Port, New District, Yueyang City ,Hunan Province, China.

Scan, mobile access

COPYRIGHT © yyrksw.com ALL RIGHTS RESERVED. Yueyang Ruikang Biotechnology Co., Ltd. ALL RIGHTS RESERVED.